CULTRUTH GLOSSARY

Simplifying seemingly complex sustainable fashion terminology

The cultruth glossary cuts the sustainable fashion jargon, giving you the knowledge to make the right choices. Here, we give you the break down of each sustainable fashion term, so that you can better understand what you're buying.

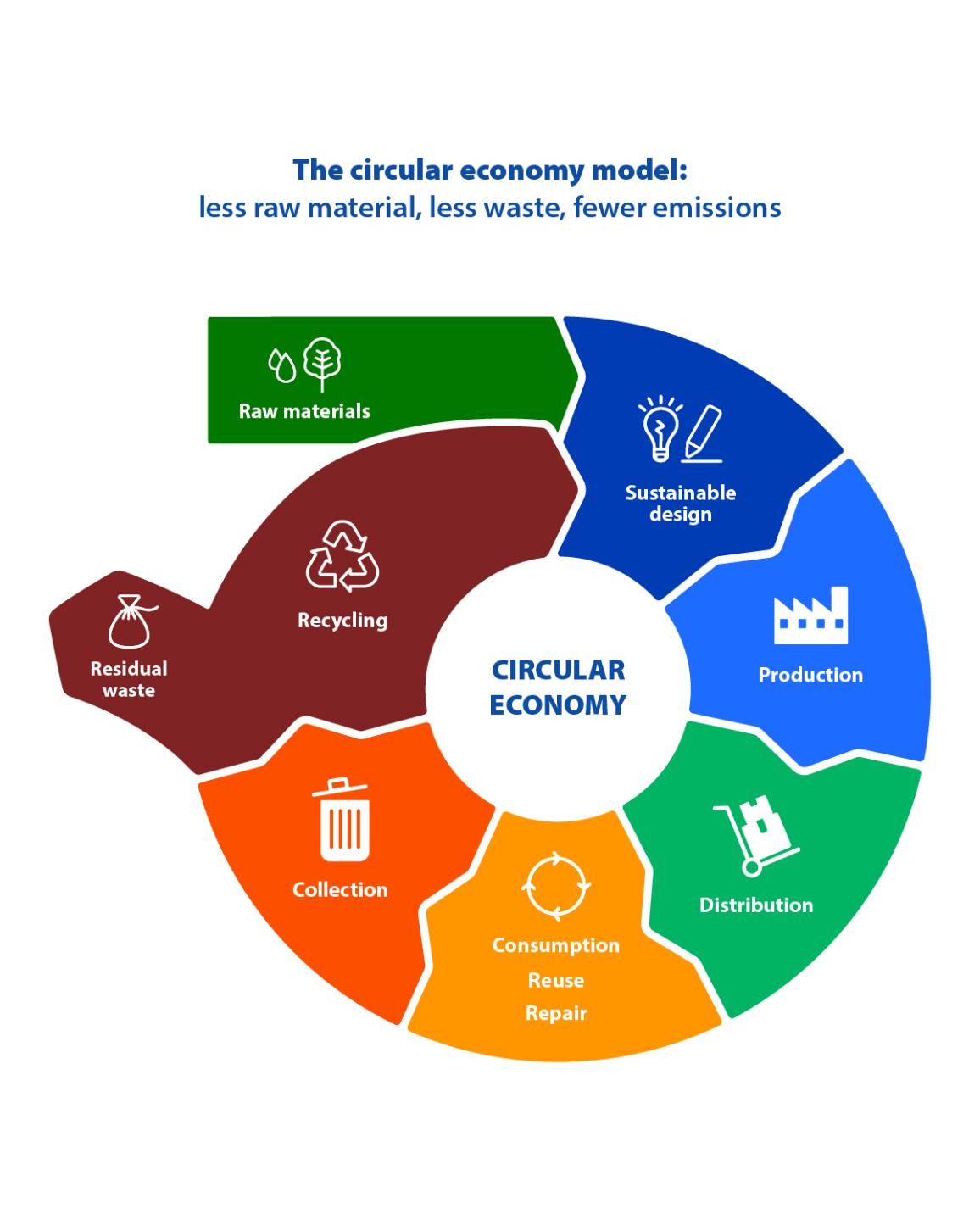

Asia Floor Wage

What is the Asia Floor Wage?

The Asia Floor Wage proposes a wage for garment workers across Asia that would be enough for workers to live on.

Based on some common factors including the number of family members to be supported, the basic nutritional needs of a worker and their dependents and their other basic needs including healthcare and education, the Asia Floor Wage is able to calculate the minimum amount needed to constitute a living wage.

The Asia Floor Wage is different in each country's national currency, but has the power to buy the same set of goods and services in all countries.

KEY TAKEAWAYS:

- The Asia Floor Wage proposes a wage for garment workers across Asia that would be enough for workers to live on

- It calculates the minimum amount needed to constitute a living wage, based on some common factors

As explained by the Asia Floor Wage website, “most of the world's garments are made in Asia, and yet the Asian workers who make them are not paid enough to live on.”

The problem the Asia Floor Wage seeks to tackle:

“The garment industry in Asia provides millions of jobs to millions of women and men, it has been behind some of the biggest economic growth in the region. But this rapid growth has come at a price - and it is the workers who are paying it.

All garment workers in Asia need a wage increase to be able to provide for themselves and their families basic needs - including housing, food, education and healthcare. However, often when workers struggle to improve their wage and conditions in one country, companies relocate to another country where wages and conditions are lower.

Workers are therefore afraid to fight for better wages because they might lose their jobs.”

C0 coating

What is C0 coating?

In order to make jackets waterproof, a coating is necessary. Previously, the most used coatings were C8 and C6 coatings, which contain PFCs that are dangerous for the environment.

The levels of fluorocarbons contained are determined by the number following the “C”.

C0, then, has no dangerous fluorocarbons, and is safe to use.

KEY TAKEAWAYS:

- A coating is necessary for jackets to be waterproof, many of which contain dangerous PFCs (such as C8 and C6)

- C0 coating contains no PFCs

Understanding C0 coating

One cannot fully grasp the value of C0 coating, without understanding the harm PFCs cause both humans and the environment.

C0 coating provides a water repellent alternative to C8 and C6 coatings (the former of which has already been banned by European countries and the US), which doesn’t contain the PFCs that are near impossible to disintegrate. This means that they remain in our bodies and environment for a very long time.

By using C0 coating, fashion brands take one more step towards reducing and eliminating their use of dangerous chemicals that impact our Planet, People, and Animals.

C8 and C6 water repellents

What is a C8 and a C6 water repellent?

C8 and C6 water repellents are types of PFCs. They contain dangerous fluorocarbons which are made of carbon and fluorine atoms.

C8 PFCs have only 8 or less perfluorinated carbon atoms - and have been banned in various countries. C6 PFCs have only 6 or less perfluorinated carbon atoms, so are considered “safer”.

PFCs are non-biodegradable and do not appear anywhere in nature.

C6 and C8 water repellents have been determined as highly toxic to humans by the Environmental Protection Agency (EPA).

KEY TAKEAWAYS:

- C8 and C6 water repellents are types of PFCs, harmful to the environment

- They are highly toxic to humans

Understanding C6 and C8 water repellents One cannot fully grasp the value of C6 and C8 coating, without understanding the harm PFCs cause both humans and the environment. C0 coating provides a water repellent alternative to C8 and C6 coatings, which doesn’t contain the PFCs that are near impossible to disintegrate. This means that they remain in our bodies and environment for a very long time. C8 coating has already been banned by many countries, including Europe and the US. Regulators are also discussing banning C6.

Carbon Footprint

What is Carbon Footprint?

Carbon footprint is the amount of greenhouse gases (including carbon dioxide and methane) emitted into the atmosphere by a particular object or individual.

KEY TAKEAWAYS:

- Carbon footprint is the amount of greenhouse gases emitted into the atmosphere by a particular object or individual.

Understanding carbon footprint

The concept of a carbon footprint grew out of the 1990s idea of an ecological footprint, which is the total area of land required to sustain an activity or population.

A variety of tools exist to calculate the carbon footprint of an object or individual. In our globalised world today, where a product’s supply chain is located in many countries, it is also often difficult to calculate the impact in each country accurately.

Individuals and organisations have begun reducing their carbon footprint through carbon offsetting, in order to reach carbon neutrality or even climate positive products and lifestyles.

Carbon Neutrality

What is Carbon Neutrality?

As implied by its name, carbon neutrality means there is no net release of carbon dioxide into the atmosphere from an activity.

More and more organisations – from shipping companies to factories – are using carbon offsetting (eg. by planting trees) and renewable energies in order to reach carbon neutrality.

KEY TAKEAWAYS:

- Carbon neutrality: no net release of carbon dioxide into the atmosphere from an activity.

- Organisations use carbon offsetting to reach carbon neutrality

Understanding carbon neutrality

In an ideal world, all activities should be carbon neutral. However, we must be aware of big companies that pollute the world, invest a huge amount in planting trees, and then call themselves carbon neutral. This avoids the root of the problem.

It is important to first reduce our carbon emissions to the maximum, and then carbon offset to reach carbon neutrality.

Carbon Offsetting

What is Carbon Offsetting?

Carbon offsetting is the action of compensating for carbon dioxide emissions arising from an activity, primarily through participating in schemes designed to make equivalent reductions of carbon dioxide in the atmosphere.

KEY TAKEAWAYS:

- Carbon offsetting: compensating for carbon dioxide emissions arising from an activity

- Usually done through schemes to make equivalent reductions of carbon dioxide in the atmosphere

Understanding Carbon Offsetting

In order to “carbon offset” an activity, one must first measure precisely how much carbon dioxide the activity is producing. Then, choose an activity that compensates for it. A classic example is planting trees.

Notably, it is often difficult to measure both of these factors accurately. For example, when producing a coat, it is hard to calculate how much energy is used in the initial fabric factory.

When building a house, if I only calculate the carbon dioxide used in construction, I am omitting the carbon dioxide emitted to make the building materials, transport them, and the quality of material used - which might impact future energy consumption in that house. As you can see, it is possible to skip certain steps in the carbon calculations.

The difficulty surrounding this issue has been demonstrated in debate over well-known carbon offsetting organisations’ effectiveness.

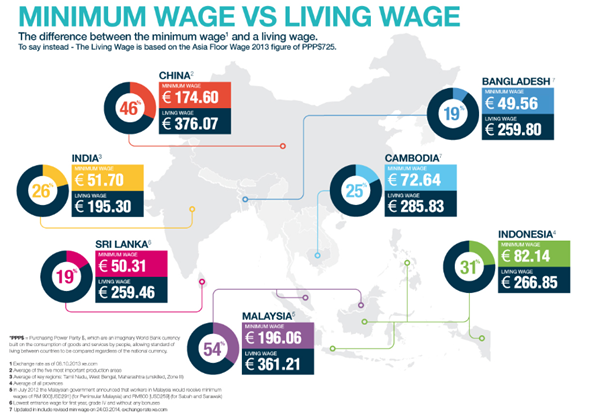

Circular Economy

Currently, our economy is linear: we take products from the Earth, use them, and then throw them away. In contrast, a circular economy reduces waste by sharing, leasing, reusing, repairing, refurbishing and recycling existing materials and products as long as possible.

By using methods to keep the product within the economy for as long as possible, the life cycle of products is extended, which is more sustainable in the long-term.

- A circular economy is a model whereby methods to extend products’ life cycles and reduce waste are used, for a more sustainable future

The benefits of a circular economy are:

- To protect the environment

Our planet is currently facing severe landscape and habitat reduction, biodiversity loss, and general raw material over-use. By using methods to reuse and regenerate the products we're already using, we don't need to extract further and destroy more nature for new products.

- Reduce raw material dependence

By recycling and reusing products, among other methods, we decrease our reliance on raw materials to create new products.

For example, by using recycled polyester fibre down insulation in a jacket, we ensure that no new material (in this case down feathers) is needed. Not only is this better for the planet, but also for the animals on it!

- Create jobs and save consumers money

Arguably, the redesign of materials and products for a more circular economy would boost innovation across different sectors of the economy, employing more people.

By using durable products, consumers save money long-term, given their high-quality and long-term use.

culthread participates in creating a more circular economy by creating products that last a lifetime. You can also contribute by ensuring that you make the most out of your culthread, and donate it if you fall out of love with it. See our guide here.

Climate Positive

What is being climate positive?

Climate positive businesses or organisations are ones whose carbon emissions are below zero. This means they have removed more carbon dioxide (CO2), than they have emitted.

Climate positive is one step further than carbon neutral. Usually, the organisation has offset the carbon dioxide further than the carbon dioxide created by the organisation.

- Climate positive businesses or organisations, are ones whose carbon emissions are below zero.

- They have removed more carbon dioxide (CO2) than they have emitted.

Understanding Climate Positive

There are currently no official accounting frameworks that would underpin a climate positive or carbon negative claim. They describe a state of removing more greenhouse gases than are emitted. This is after emissions have been reduced across all scopes to a minimum level that is aligned with science.

Coffee-Cycled Vegan Leather (RVL)

What is Coffee-Cycled Vegan Leather?

Coffee-cycled vegan leather is a type of recycled vegan leather (RVL). It is cruelty-free leather made from coffee grounds (29%), and recycled polyester fabric (31%). The fabric has a water-based PU coating (40%), which does not use harmful chemicals (like certain other PU coating) and gives it the look and feel of leather.

When making an espresso based coffee, only 1% of the coffee gets used and 99% gets thrown away. Utilising more waste materials, instead of them ending up in landfills benefits the environment, by making our industries more circular. Here, coffee grounds and polyester are turned into fabric for the recycled vegan leather.

KEY TAKEAWAYS:

- Coffee-cycled vegan leather (RVL) is made from 29% coffee grounds, 31% recycled polyester, and 40% PU coating

- 99% of coffee grounds are disposed of as waste, using them to create fabric makes the fashion industry more circular

Understanding Coffee-Cycled Vegan Leather

How are coffee grounds turned into fabric?

Coffee grounds can be transformed into yarn through a temperature of 160°C for carbonisation, which is energy efficient in comparison to 600°C for normal yarn. The basic procedure to obtain the coffee-based fibre yarn includes mixing the coffee residue into a recycled plastic bottle material and re-polymerising (creating new compounds) to create the yarn.

The raw material is a combination of coffee and recycled polyester; the finished textile quality and appearance are as good as those achieved by using new materials.

See more details here.

What are the benefits?

The benefits of coffee-cycled vegan leather are similar to that of fruit-cycled vegan leather and recycled vegan leather (RVL).

- Better for the planet

When used coffee grounds end up in landfill, methane, a greenhouse gas that is 30 times more potent than carbon dioxide (CO2), is emitted. Coffee-cycled vegan leather reduces the amount of coffee grounds ending up in those landfills, and therefore also the methane emitted.

Using fruit-cycled vegan leather avoids the animal cruelty and harmful toxins produced by the tanning process produced by real leather , and the ecologically toxic PVC used in some vegan leather.

- Coffee fibres are naturally deodorising

- Naturally anti-bacterial

Coffee-Cycled Vegan Leather can be used for shoes, jackets, and much more.

Check out our long-form Cultruth Explainer about everything you need to know about leather.

Check out culthread’s Recycled Vegan Leather here to see how the fabric comes to life.

CLO Technology

What is CLO Technology?

CLO technology is a 3D CAD application that enables fashion ateliers to simulate prototypes digitally, and alter them based on the digital prototype. This helps ateliers avoid creating a prototype, determining changes, creating it again, and so on, every time there is a change.

By simulating the prototype almost exactly, we are able to make changes digitally first.

This technology is eco-friendly as it uses much less resources than re-creating a product each time there is a change to be made.

KEY TAKEAWAYS:

- CLO technology enables fashion ateliers to simulate prototypes digitally

- It facilitates rapid change in prototypes, and saves precious resources that would be used to iterate the prototype otherwise

Deadstock (Designer)

What is Designer Deadstock?

Designer Deadstock is left-over material from manufacturing that cannot be reused as the product line or series is over. Quite literally “dead” – “stock”: deadstock. Given that brands often order extra material, in case of defects or issues during the manufacturing, deadstock material is regularly left over – and tossed away.

Deadstock has a significant carbon footprint, as material – whose manufacturing already emitted significant amounts of carbon dioxide – goes to waste.

Note: dead stock is also used to describe unsellable inventory, or inventory that can no longer be sold in stores.

KEY TAKEAWAYS:

- Deadstock is left-over material from manufacturing that cannot be reused as the product line or series is over.

- There is often deadstock material, as brands order extra material, in case of defects or manufacturing issues.

- Unused deadstock leaves an important carbon footprint.

Understanding Designer Deadstock

Before a garment is available for sale, about 35% of all materials in the supply chain ends up as ‘waste’ (2017) – there could be cutting waste, damage in transport or production, and excess stock (deadstock) that is sometimes incinerated.

Rescued designer deadstock materials are leftover fabrics from clothes production, often owing to buffer stocks, which would otherwise end up as waste. When large brands order fabric for their collections, they normally order a buffer stock so that if they need to produce more of the same items, the fabric is in stock, and identical to what has been used previously. Unfortunately, this means that there is often fabric that is leftover and unused – these fabrics may be burnt or sent to landfill.

Note that we are not talking about seconds or damaged fabrics – though some call these types of fabrics ‘deadstock’ as well. Here we are talking about ‘rescued designer deadstock’ only as defined above – we never produce with seconds or damaged stock materials.

It is also different to factory production deadstock, which occurs higher up in the supply chain (the mills), and is arguably easier to use.

Deadstock (Factory Production)

What is factory production deadstock?

Factory production deadstock is the excess fabric that a factory mill produces. This is different to designer deadstock, which is the fabric left over from manufacturing clothes.

Factory mills produce fabric by large quantities and once an order is complete, there is often excess fabric which the mill made for samples, or in case of issues with the quantity ordered. Depending on the factory mill, this fabric will sometimes go to waste.

KEY TAKEAWAYS:

- Factory production deadstock is the excess fabric that a factory mill produces, which sometimes goes to waste

Understanding factory production deadstock

Before a garment is available for sale, about 35% of all materials in the supply chain ends up as ‘waste’ (2017) – there could be cutting waste, damage in transport or production, and excess stock (deadstock) that is sometimes incinerated.

In a similar way to designer deadstock, factory mills produce larger quantities than the fabric order, for sampling, or in case of any production issues.

Note that we are not talking about seconds or damaged fabrics – though some call these types of fabrics ‘deadstock’ as well. Here we are talking about ‘rescued deadstock’ only as defined above – we never produce with seconds or damaged stock materials. We also do our best to use recycled deadstock materials.

Down

What is down?

Down (sometimes called “down feather”) is the chest region plumage of geese and ducks, a layer of fine feathers found under the tougher exterior feathers.

It is used as a thermal insulator and padding in jackets, mattresses, pillows, etc.

Recently, the animal cruelty behind down has been revealed (details in "Understanding Further").

KEY TAKEAWAYS:

- Down is the chest region plumage of geese and ducks

- It is used as a thermal insulator and padding

- Much animal cruelty unfortunately goes on in the down industry

Understanding down

Several years ago, it became apparent that birds in the down supply chain had been force fed in order to massively inflate their livers for foie gras. We also learned that it was common industry practice to pluck down feathers from birds while they were alive, a practice that was exacerbated by the fact that the quality of down improves as a bird ages. Sometimes birds are left with gaping wounds, or die as a result of this process (warning: this video is graphic). Peta took undercover video footage showing large scale down farms live-plucking birds inhumanely, causing considerable injury and distress to the birds.

As a result, some of the better-known brands have joined the ‘Responsible Down Standard’ which aims to conduct an annual audit of affiliated down suppliers to avoid “unnecessary harm”. Peta insists that it is impossible to know whether the down that you buy has been taken from live-plucked birds and that the only way to stop this process is by consciously choosing cruelty free materials. They visited a number of farms (often multiple times) to investigate live-plucking and estimated that nearly half of Chinese suppliers admitted to selling live-plucked down wholesale. China is the worlds leading supplier of down, producing about 80% of global supply.

So, what is the alternative? Recycled fibre down insulation: Synthetic down doesn’t get mouldy and is allergen free; the latest technology has produced light and warm fibre down that closely resembles the animal kind. Even better - it can be made from recycled material!

Check out our blog to find out more.

Check out our supply chain details to see how culthread does it.

Energy Cost of Recycling

What is the Energy Cost of Recycling?

Recycling involves the processing of materials, which requires using energy, through the use of machinery and equipment (along with labour). This then raises the question: is the carbon dioxide emitted by the energy used to recycle offset by the carbon dioxide saved through recycling? In short, does recycling have an overall positive impact on the planet?

In most cases, recycling is energy efficient (and thus positive), because processing recycled materials uses less energy than processing new materials.

KEY TAKEAWAYS:

- Recycling requires energy consumption, which begs the question regarding the net carbon emissions.

- Generally speaking, the overall energy consumption of the recycling process is lesser than that of creating new materials from scratch.

You can read more about the energy cost of recycling in this detailed article.

Fittings

What are Fittings?

In the fashion industry, fittings are everything beyond the core fabric of a product. For example, fastenings, zips, buttons, etc.

Note: these are not the fittings to check if clothes fit properly.

KEY TAKEAWAYS:

- Everything beyond the core fabric of a product, such as zips and buttons

- Not to check if clothes fit well!

Understanding fittings

More and more recycled fittings are being created in the market, such as SAB’s recycled zippers.

Fruit-Cycled Vegan Leather (RVL)

What is fruit-cycled recycled vegan leather (RVL)?

Fruit-cycled vegan leather is a type of recycled vegan leather (RVL). This vegan leather which uses recycled agricultural waste as a base material, with water-based PU coating and an artificial grain pattern applied on top.

Some fruit-cycled vegan leather has been made from the Italian wine industry’s agricultural waste. Others have been made from waste pineapple leaves.

Using a sustainability sourced textyle, along with a water-based PU coating, is much better for the environment than PVC [LINK]-based vegan leather, or real leather, and it harms no animals!

KEY TAKEAWAYS:

- Fruit-cycled vegan leather uses recycled agricultural waste as a base material, with water-based PU coating and an artificial grain pattern applied on top

- Fruit-cycled RVL is one of the most sustainable leather alternatives, along with coffee-cycled vegan leather.

Understanding fruit-cycled recycled vegan leather

As an example, take pineapple-based fruit-cycled vegan leather, which has been called Piñatex®. Piñatex® is a sustainably sourced textile, made from a natural waste product, created with low water use and low production waste, and containing no harmful chemicals or animal products.

Using fruit-cycled vegan leather avoids the animal cruelty and harmful toxins produced by the tanning process produced by real leather , and the ecologically toxic PVC used in some vegan leather.

Check out our long-form Cultruth Explainer about everything you need to know about leather.

Global Living Wage

What is the Global Living Wage?

The Global Living Wage is the living wage determined by the Global Living Wage Coalition (GLWC).

The GLWC provides high quality and consistent knowledge and information about living wage levels, implementation, with a mission to enable workers around the world to afford a decent life for themselves and their families.

The GLWC shares resources on benchmark countries, including Vietnam, and on case studies.

KEY TAKEAWAYS:

- The living wage is determined by the Global Living Wage Coalition as one that enables workers to afford a decent life for themselves and their families.

Global Recycled Standard (GRS)

What is the Global Recycled Standard (GRS)?

The Global Recycled Standard (GRS) is a global standard owned by the Textile Exchange.

The GRS is an international, voluntary, full product standard that sets requirements for third-party certification of recycled content, chain of custody, social and environmental practices and chemical restrictions – among other requirements.

Companies can receive GRS certification for products and materials.

KEY TAKEAWAYS:

- The GRS is a global standard that sets sustainability requirements, including recycled content, environmental practices, and chemical restrictions.

- Materials and products can receive GRS certification.

Understanding GRS

The Global Recycle Standard (GRS) was originally developed by Control Union Certifications in 2008 and ownership was passed to the Textile Exchange on 1 January 2011.

- Recycled Material is Recycled

The materials and products claimed to be recycled must meet the international standard definition of recycled, regardless of whether it is post or pre-consumer material [LINK]. Traceability [LINK] of these materials through the supply chain is key to ensuring that materials used in end products are certifiable. The identity of the recycled materials must be maintained from the recycler to the final product. To do this, every stage of the supply chain must be certified through third-party, on-site audits and document reviews. [Ref to https://idfl.com/2022/03/28/global-recycled-standard/]

- Products are Produced Responsibly

GRS sites, in particular, are rigorous in their requirements when it comes to social, chemical, and environmental impacts. Requirements for chemical use for any Certified Organization include having a Chemical Management System. This system has dedicated staff to monitor chemical usage, adequate mechanisms to monitor any chemicals used on site and specific procedures relating to training staff on the use of chemicals and the Chemical Management System itself.

- Chain of Custody

Understanding and identifying the chain of custody allows the certifier to see the recycled material from the beginning as a recycled material to its final destination in a consumer or material product.

- Credible certification

The use of third-party certification bodies ensures that the certification is credible. These professional certification bodies examine each stage of the material in the supply chain.

- Prestigious Labelling

Any products that successfully make it through the certification process can be labelled with their respective designations, whether Recycled Claim Standard or Global Recycled Standard.

- Worldwide Industry Engagement

These designations are discussed, debated, and decided upon by a collection of suppliers, retailers, brands, and recyclers from all marketplace sectors.

See culthread's GRS certification here.

Green dry-cleaning

What is green dry-cleaning?

Dry-cleaning involves processing clothes in a liquid solvent to remove soil and stains. The majority of dry cleaners still use perchloroethylene or "perc" today as their primary solvent.

“Perc” is a harmful solvent, which the United States Environmental Protection Agency (EPA) considers both a health and environmental hazard.

Green dry cleaning refers to any alternative dry cleaning method that does not involve the use of perc.

KEY TAKEAWAYS:

- Green dry-cleaning is dry-cleaning that uses sustainable alternatives to the harmful “perc” solvent

Understanding green dry-cleaning

The different green dry-cleaning methods are, according to The Spruce:

- “Wet Cleaning

Wet cleaning uses water and specialised detergents that are milder than home laundry products to clean clothes. Wet cleaners have computerised washers and dryers and professional pressing, steaming, and finishing equipment to help your clothes look their best.

The EPA considers it one of the safest professional cleaning methods, saying that it is "an example of an environmentally-preferable technology that can effectively clean garments." [reference Design for the Environment. United States Environmental Protection Agency with the Garment and Textile Care Industry.]

Extra care is taken before and after cleaning to treat stains since no chemical solvent is used.

- Liquid Carbon Dioxide Cleaning

Carbon dioxide (CO2) cleaning uses liquid CO2 as the cleaning solvent along with detergent. The liquid CO2 is formed by placing the non-flammable and nontoxic gas under high pressure. Liquid CO2 is non-toxic and is actually used to provide carbonation to soft drinks.

Clothes are placed in what appears to be a traditional dry cleaning machine and the ambient air is sucked out. The cleaning drum is then injected with carbon dioxide in both gas and liquid form. After the clothes are cleaned, the liquid CO2 is pumped back into a holding tank for reuse.

The process is, perhaps, the most environmentally-friendly because the CO2 is captured as a by-product of existing industrial processes; its impact on global warming is minimal. The process uses less energy than traditional dry cleaning because there is no solvent to heat.

While CO2 is naturally occurring and inexpensive, the dry cleaning machines cost around $150,000 each or three times more than a traditional model. This makes them cost prohibitive for many small businesses.

- DF-2000 Hydrocarbon Solvent

Some cleaners promote themselves as green by using an "organic" solvent called DF-2000. This solvent is a hydrocarbon that must be made from petroleum. Production of these chemicals raises environmental concerns, in particular, over greenhouse gases.

- Silicon-Based Solvent

Some cleaners use the GreenEarth cleaning method to replace perc. GreenEarth is basically liquified sand (SiO2). It functions as a silicone-based solvent called siloxane or D-5. Siloxane is similar to some of the base ingredients used in shaving creams and deodorant. When GreenEarth is discarded, it breaks down into sand, water, and carbon dioxide.

The good news is that no chemicals touch your clothes. However, the manufacture of siloxane uses chlorine, which releases carcinogenic dioxin during the manufacturing process.”

Greenwashing

What is greenwashing?

Greenwashing is when a company uses false or misleading claims suggesting they are doing more for the environment than they actually are.

Now that consumers have become more eco-friendly and sustainability-conscious, many companies are tempted to do so, and the terms “sustainable”, “ethical”, and “eco-friendly” get thrown around a lot.

KEY TAKEAWAYS:

- Greenwashing is when a company uses false or misleading claims suggesting they are doing more for the environment than they actually are.

- Nowadays, more and more companies are greenwashing their customers to drive their sales

Understanding greenwashing

Greenwashing is a term that dates back to 1986, created by environmentalist Jay Westervelt in an era where consumers didn’t have the luxury of extensive fact-checking that we have today.

A key example of greenwashing is the fast fashion industry. In essence, since fast fashion is producing items that will likely be thrown away rapidly, it is not sustainable [link to definition of sustainable].

Let’s look at H&M:

H&M is a key example when it comes to greenwashing, which doesn’t come as much of a surprise when it is one of the top fast-fashion brands. H&M may appear to be at the apex of fashion sustainability; they came first in Fashion Revolution’s Fashion Transparency Index 2020 which focuses on transparency and disclosure, and have made a number of new ‘green’ claims, one of which is a pledge to use only sustainable or recycled materials by 2030. However, in the past, H&M has said that they “rarely” burn unsold clothes, though some estimate that they have been doing large amounts of burning for a number of years. Ultimately, the massive overproduction by H&M of cheap, fast-fashion items is incredibly harmful for the planet.

The reality is, a holistically sustainable brand should take into account social justice factors such as safe factory conditions, equal pay, garment worker rights and more, as well as environmental factors. Those that are truly sustainable should have nothing to hide and therefore be confident in sharing this information, addressing each of these factors and demonstrating accountability and traceability. They should be able to provide facts to back up what they say.

Landfills

What are landfills?

A landfill site, also known as a tip, dump, rubbish dump, garbage dump, or dumping ground, is a site for the disposal of waste materials. Landfills are the oldest and most common form of waste disposal.

Modern landfills are well-engineered and managed facilities for the disposal of solid waste, although this is unfortunately not always the case.

Landfills often leak, thus damaging the environment and human health. The methane that is released due to the decomposing waste is a potent greenhouse gas that contributes to global climate change.

KEY TAKEAWAYS:

- Landfills are sites for the disposal of waste materials

- Modern landfills are well-engineered and managed facilities

- However, some landfills leak or are poorly managed, leading to damage to both the environment and human health

Understanding landfills

Despite landfills being the oldest form of waste disposal, the systematic burial of the waste with daily, intermediate and final covers only began in the 1940s.

Why are landfills bad?

- Nowadays, everyday products that are used and thrown away contain more toxic chemicals than ever before. When these products end up in landfills or incinerators, the toxins pollute the air we breathe and the water we drink.

- The methane that is released due to the decomposing waste is a potent greenhouse gas (worse than carbon dioxide) that contributes to global climate change.

- The air pollutants escaping from the landfill can also cause respiratory problems in people who live close to the landfill.

- If the leachate leaks from landfills, it can bring toxins from the landfill into nearby groundwater supplies. Given that landfills are more often constructed near low-income neighbourhoods. Due to this injustice, these people are more likely to experience the health risks associated with landfills.

How to solve these issues? Recycle more!

Legal Minimum Wage (LMW)

What is the Legal Minimum Wage?

According to the ILO (International Labour Organisation), the legal minimum wage is “the minimum amount of remuneration that an employer is required to pay wage earners for the work performed during a given period, which cannot be reduced by collective agreement or an individual contract”.

Note that this is different from country to country.

KEY TAKEAWAYS:

- The minimum amount of remuneration an employer is required to pay wage owners before the law

- It varies depending on the country

Understanding the Legal Minimum Wage

While the legal minimum wage is a legal requirement for companies, in some countries the LMW is particularly low. In such countries, the legal minimum wage has often not been updated to account for inflation, leading to workers being unable to live off this wage.

Therefore, it is useful to use organisations, such as the Global Living Wage Coalition [link] and the Asia Floor Wage [link], as benchmarks for reasonable wages on which workers can live on.

Organic Cotton

What is organic cotton?

Organic cotton is grown using methods and materials that have a low impact on the environment.

Third-party certification organisations verify that organic producers use only methods and materials allowed in organic production.

In addition, country regulations often prohibit the use of genetically engineered seed for organic farming.

KEY TAKEAWAYS:

- Organic cotton is cotton grown using methods and materials that have a low impact on the environment, unlike traditional cotton growing

Understanding organic cotton

In order to have the lowest possible impact on the environment, organic cotton production systems replenish and maintain soil fertility, reduce the use of toxic and persistent pesticides and fertilisers, and build biologically diverse agriculture – among other factors.

In addition to being one of the most widely grown crops in the world, growing conventional cotton is also one of the most chemical-intensive. These chemicals have a terrible impact on the earth’s air, water, soil, and the health of people in cotton-growing areas. They are among the most toxic chemicals as classified by the Environmental Protection Agency.

The problem is even worse in developing countries with uninformed consumers, and lack of stable institutions and property rights. In addition to destroying the land, thousands of farmers die from exposure to these chemicals every year.

See this great info sheet for further information about organic cotton.

PET

What is PET?

PET stands for PolyEthylene Terephthalate, a type of plastic. It is commonly used in water bottles and different beverage containers.

It is the most recycled plastic out of all seven plastic categories. It can easily be washed, broken down and turned into raw materials.

PET is not biodegradable, meaning that it’s essential to recycle it.

PETA

What is PETA?

PETA stands for the People for the Ethical Treatment of Animals. It is the largest animal rights organisation in the world, and PETA entities have more than 9 million members and supporters globally.

PETA opposes speciesism, a human-supremacist worldview, and focuses its attention on the four areas in which the largest numbers of animals suffer the most intensely for the longest periods of time: in laboratories, in the food industry, in the clothing trade, and in the entertainment business.

How is a business certified as cruelty-free by PETA?

Companies listed either signed PETA’s statement of assurance or provided a statement verifying that they do not conduct or commission any animal tests on ingredients, formulations, or finished products and that they pledge not to do so in the future.

KEY TAKEAWAYS:

- PETA is the most renowned international certification for cruelty-free organisations

- PETA stands for People for the Ethical Treatment of Animals, and is the largest animal rights organisation in the world

Further information about PETA can be found on the website.

Post & Pre-Consumer Recycling

What are Pre & Post-Consumer Recycling?

Pre-consumer recycling, is recycling of material from manufacturer waste that never actually made it to the consumer for one reason or another: scraps, rejects, trimmings.

Post-consumer recycling, is recycling of waste that’s been used by a consumer, disposed of, and diverted from landfills—stuff like the aluminium cans and newspapers that you place in your recycling bin for pick-up.

KEY TAKEAWAYS:

- Pre-consumer recycling is recycling of material before it gets to a consumer

- Post-consumer recycling is recycling of material after it has been used by a consumer

Understanding Pre & Post-Consumer Recycling

It is argued that post-consumer recycling is more valuable than pre-consumer recycling. This is because factories are incentivised to find ways to use the material, whereas post-consumer recycling is recycling material that is already bound for landfills. The stuff that ends up on the factory floor can be repurposed into something new rather than trashed.

Poly-fluorinated Chemicals (PFC)

What is a PFC?

A PFC is a man-made chemical used in heat, water and stain repellent coatings and membranes, as water-repellant agents. It is not found anywhere in nature, and doesn't break down in nature, which is very harmful to the environment and human bodies.

A PFC can be used in a variety of products, including clothing, furniture, adhesives, food packaging, electrical wire insulation, and more.

There is a growing body of evidence showing that exposure to PFCs are toxic to humans and ecosystems, although the extent of it is still being researched.

KEY TAKEAWAYS:

- PFCs are man-made chemicals with strong molecular bonds that don’t break down in nature.

- They are used in heat, water, and stain repellent coatings and membranes, for a wide variety of products.

- The potential harm caused by PFCs is still being researched, it is clear that the contamination of water and food is harmful to both humans and wildlife.

Understanding PFCs

Due to their strong molecular bonds, PFCs do not readily break down. It has become clear that PFCs are very harmful to the environment, and whilst there are many sources of PFCs within the clothing sector, half of the most hazardous ones are used for weatherproof clothing.

Every time we wash apparel that is PFC-treated, the process removes the chemicals and they end up going down the drain. PFCs are not filtered out by municipal waste treatment plants, which is why we find PFCs in lakes, rivers and oceans. Once released into the environment they remain there for a very long time and are widely dispersed.

PFCs persist in the environment and in our bodies. In fact, the National Health and Nutrition Examination Survey (NHANES), carried out by the Centers for Disease Control, detected four types of PFCs in over 98% of blood samples, representative of the U.S. population, collected in 2003-2004.

Because one of these PFCs called C6 is not currently banned, you will find this toxin in most sports apparel, hiking jackets, and carpets. The good news is that Europe is currently considering a German-led proposal to restrict C6 PFCs from coming onto the market.

Until fairly recently there were very few alternatives. Now, there are – including the CO coating for water repellency culthread uses (without any PFCs, or C0).

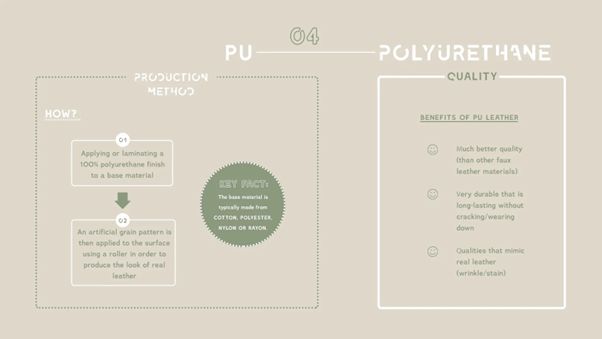

PU Coating

What is PU coating?

PU (polyurethane) is a composite material made of: (1) one or more layers of polymer resins joined by urethane links; and (2) a woven or non-woven textile backing such as polyester, cotton, nylon, or ground leather.

The PU coating is applied to a single side of the base fabric. Then, an artificial grain pattern is then often applied to the surface using a roller in order to produce the look of real leather. This makes the fabric water resistant, lightweight and flexible.

Please note: PU coating can still contain toxic chemicals. Water-based PU coating, however, does not.

KEY TAKEAWAYS:

- PU (polyurethane) is a composite material made of: (1) one or more layers of polymer resins joined by urethane links; and (2) a woven or non-woven textile backing such as polyester, cotton, nylon, or ground leather

- An artificial grain pattern added to the fabric produces a leather look

- PU coating can still contain toxic chemicals. Water-based PU coating, however, does not

Please read more about PU coating in this detailed article.

PU Vegan Leather

What is PU vegan leather?

PU (polyurethane) leather is made by applying or laminating a 100% PU coating (also called polyurethane finish) to a base material which typically includes cotton, polyester, nylon or rayon.

An artificial grain pattern is then applied to the surface using a roller in order to produce the look of real leather.

KEY TAKEAWAYS:

- PU leather is made by applying PU coating to a base material, and adding an artificial grain pattern to produce the look of real leather

Understanding PU vegan leather

PU vegan leather is a composite material made of: (1) one or more layers of polymer resins joined by urethane links; and (2) a woven or non-woven textile backing such as polyester, cotton, nylon, or ground leather. The PU coating is applied to a single side of the base fabric and then treated to look more like animal hide. This makes the fabric water resistant, lightweight and flexible. This fabric then provides the most realistic imitation of leather when it comes to its soft and supple feel. When stitched, gathered, or tufted it actually “breaks'' or wrinkles like real leather.

What impact does PU leather have on our Planet, People, and Animals?

In terms of sustainability, PU leather is much better than real leather as its production uses less resources. Also, unlike PVC vegan leather, PU doesn’t release harmful substances and dioxins during usage or disposal and is therefore considered to be more eco-friendly (but still not perfect).

PU accounts for less than 2% of the plastic waste in our oceans, compared to 95% of thermoplastics. One reason for this low level of waste is that polyurethane lasts much longer than most thermoplastics.

PU leather is entirely artificial and therefore no animals are harmed in the making of the product. There are however, some types of PU leather called bicast or split leather include actual leather with a polyurethane coating on top, so if you are looking for a 100% vegan leather alternative, be sure to look into the product to ensure it is PU only.

What’s the quality of PU vegan leather like?

In comparison to other faux leather materials, PU leather is much better quality and is very durable. PU leather can also wrinkle and stain just like real leather and lasts a very long time without cracking or wearing down, meaning that any items will remain in good condition for a longer period of time.

Check out our long-form Cultruth Explainer about everything you need to know about leather.

Polyvinyl Chloride (PVC)

Polyvinyl Chloride (PVC) is one of the most commonly used thermoplastic polymers worldwide. It is known for being dense, hard, and strong, and is cheap (relative to other plastics). It has been labelled by Greenpeace as the “single most environmentally damaging type of plastic” due to its short durability, and non-biodegradable or degradable nature.

- Polyvinyl Chloride (PVC) is one of the most commonly used thermoplastic polymers worldwide.

- PVC is strong and cheap

- PVC's non-biodegradable nature means that it is particularly damaging to the environment

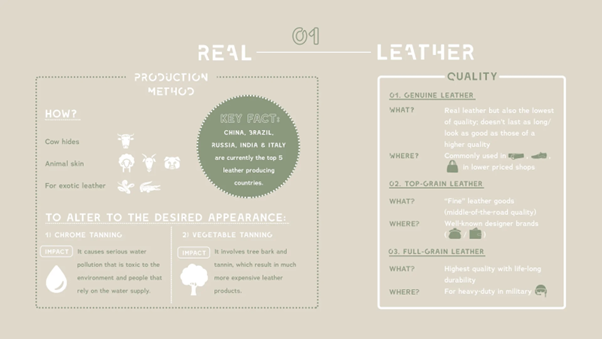

Real Leather

What is real leather?

Real leather is most commonly made from cow hide (skin) but is also made from animal skin derived from sheep, goats and pigs to name a few, as well as snakes and alligators when creating more exotic leathers

The animal skin is then processed through various tanning methods for the desired appearance.

Two methods are most commonly used:

- “Chrome tanning” – the most commonly used, which results in serious water pollution that is toxic to the environment and the people that rely on the water supply and ecosystem.

- “Vegetable tanning” – a long, challenging process involving tree bark and tannin, which in turn results in much more expensive leather products

It’s been argued that since leather is typically a by-product of the meat industry, leather goods are ethical. On the other hand, the meat industry is arguably entirely unethical, and so a product coming from it is too. This is a topic of continuous debate – PETA [link] breaks it down well here.

The production of real leather uses large amounts of water. The manufacturing of a leather biker jacket, for instance, uses enough water for a person to drink for 36 years.

KEY TAKEAWAYS:

- Real leather is most commonly made from cowhide

- The animal skin is then processed through various tanning methods for the desired appearance - most commonly “chrome tanning”.

- There is continuous debate as to whether leather is ethical

Understanding real leather

China, Brazil, Russia, India and Italy are currently the top five leather producing countries, acquiring the animal hides and then transporting these around the world to be processed and transformed into various leather goods.

So how is real leather made?

(1) Obtaining animal hides

In the best cases, the skin of cows killed for eating are removed and dried in the sun or with salt. This is to avoid the hide from decomposing.

(2) Tanning

Tanning is a process that stabilises the proteins of the raw hide to increase their thermal, chemical and microbiological stability, making them suitable for a wide variety of end applications.

Tanning is a complicated process, involving approximately 20 stages and 250 chemicals (including toxins and heavy metals such as hexavalent chromium, aldehyde, cyanide, zinc and lead) to halt decomposition, which are extremely damaging to both people and the environment.

The primary difference between raw and tanned hides is that raw hides dry out to form a hard, inflexible material that, when rewetted, will decay, while tanned material dries to a flexible form that does not decay when rewetted.

Hair is usually loosened through the liming process, using a mixture of lime and water, and the removal is completed by machine. The hide is then washed, delimed, bated (the enzymatic removal of non fibrous protein to enhance colour and suppleness), and pickled (to provide a final cleansing and softening).

(3) Processing

Following the basic tanning process, the pelts (parts) are thoroughly dried and dyed for the desired colour. Blended oils and greases are then incorporated into the leather to lubricate it and to enhance its softness, strength, and ability to shed water.

The different qualities of real leather

- Genuine leather: the lowest quality. Typically, genuine leather doesn’t last as long or look as good as those of a higher-quality and is commonly found in belts, shoes and bags found in lower-priced stores.

- Top-grain leather: usually found in ‘fine’ leather goods. It is a middle-of-the-road quality of leather that is used by many well-known designer brands for items such as purses or wallets.

- Full-grain leather: regularly used for heavy-duty leather items used within the military. Full-grain leather is widely recognised as the best and highest-quality leather that money can buy, and with its durability it is almost guaranteed you will have the item for the rest of your life.

Check out our long-form Cultruth Explainer about everything you need to know about leather.

Recycling

What is recycling?

Recycling is the process of turning waste into usable material. This process is different for each material, impacting the energy consumption used, and how easy it is to recycle.

One of the most commonly recycled materials is polyester.

Recycling materials reduces the amount of materials which end up in landfills or other waste disposal techniques that negatively impact our planet.

KEY TAKEAWAYS:

- Recycling is the process of turning waste into usable material.

- Recycling is one of the most sustainable waste disposal techniques (along with composting)

Understanding recycling

Recycled Fibre Down Insulation

What is recycled fibre down insulation?

Fibre down insulation has traditionally been the synthetic alternative thermal insulation to down feathers.

Recycled fibre down insulation uses recycled PET water bottles to make the fibre down - making it more sustainable and ethical. These bottles would have otherwise gone to the landfill.

Recycled fibre down insulation is vegan, as it completely substitutes the goose feathers usually used.

Note that different fibre down insulations are 100%, partly, or not made from recycled materials.

KEY TAKEAWAYS:

- Recycled fibre down insulation is a sustainable alternative to down feathers

- Recycled fibre down insulation is a durable thermal insulation, recycled from post-consumer PET bottles

- Recycled fibre down insulation is vegan

Understanding recycled plastic insulation

Outerwear insulated with recycled fibre down insulation can save some 20 PET bottles per garment (or more), if considering both lining and insulation. Using PET bottles instead of oil will help protect energy reserves for future generations.

Additionally, recycled fibre down insulation does not require special quilting restrictions or fabrics, and can be washed and/or dry-cleaned with confidence.

There are different brands making recycled fibre down insulation , the most famous being Thermore. The key is to check the percentage of the fibre down that is recycled, and whether they are GRS-approved and PETA-approved. After that, it comes down to the warmth to weight ratio.

Recycled Polyester (rPET)

What is recycled polyester (rPET)?

Recycled polyester (rPET) is melted down existing plastic (PET), made into new polyester fibre.

It can be made from plastic bottles and containers thrown away by consumers or from both post-industrial and post-consumer input materials. In this way, it gives a second life to a material that’s not biodegradable and would otherwise end up in landfills or the ocean.

Recycled polyester (rPET) is just as good as virgin polyester, but takes fewer resources to make. Given that polyester accounts for 60% of the world’s production of polyester, using rPET would have a massive impact on global energy and resource requirements.

KEY TAKEAWAYS:

- Recycled polyester is melted down existing plastic, made into new polyester fibre.

- Recycled polyester (rPET) is just as good as virgin polyester, but takes fewer resources to make

- Using rPET both gives a second life to non-biodegradable materials, and provides an alternative to the high PET consumption requirement of “normal” polyester.

Understanding Recycled Polyester (rPET)

10 used plastic bottles yield enough fibre for the shell of one Culthread jacket, with another 10 bottles used in the insulation for a winter puffer jacket

As mentioned, if the fashion industry used exclusively rPET instead of virgin PET for their polyester, it would have a massive positive impact on global energy and resource requirements.

So why doesn’t the whole industry just use rPET instead of new polyester?

It’s more expensive. As consumers we’re used to clothes costing a fraction of what they should cost, and it’s much more lucrative for fast fashion companies to sell cheaper, lower quality products than focus on using sustainable fabrics and ethical practices which would push their prices up.

Recycled Vegan Leather (RVL)

What is recycled vegan leather (RVL)?

Recycled vegan leather is made by applying PU coating onto a recycled base fabric. Then, an artificial grain pattern is then applied to the surface using a roller in order to produce the look of real leather.

It is similar to PU vegan leather, but instead of using a new base material, recycled vegan leather uses a recycled base material. Recycling plastic as a base material avoids that plastic ending up in landfills.

KEY TAKEAWAYS:

- Recycled vegan leather is made of a recycled base fabric, with PU coating and an artificial grain pattern applied on top

- Recycled vegan leather is sustainable as the water-based PU coating does not contain toxins, and the base is made of recycled plastic, otherwise destined for landfill

Understanding Recycled Vegan Leather

Check out our long-form Cultruth Explainer about everything you need to know about leather.

SAB

What is SAB?

SAB is a GRS-approved company, which recycles materials, such as PET, resin, brass, and zinc, to make recycled zippers.

SAB also uses the latest technology to reduce their water consumption by 50%, with 45% repeated reuse of water, and zero emissions of toxic and hazardous chemicals (2020). They are certified by WRAP and BSCI.

KEY TAKEAWAYS:

- SAB is a GRS-approved company, which makes recycled zippers, while emitting zero toxins and using the least water consumption possible.

Understanding SAB

For recycled polyester (rPET), SAB uses a recycling process that converts waste post-consumer plastic into fibres that are reused to make zippers, pullers and other fittings, like in the diagram below. More information on the recycled fittings that we use can be found here.

Slow Fashion

What is slow fashion?

Slow fashion is the opposite of fast fashion. That means fashion that is meant to last a lifetime, and become worn and torn slowly.

By making products last longer, we produce less, and therefore reduce the pollution emitted.

KEY TAKEAWAYS:

- Slow fashion is the opposite of fast fashion

- Slow fashion means fashion that lasts a long time, and is slow to deteriorate

- Slow fashion reduces pollution, by reducing the amount of fashion products produced

Understanding slow fashion

A slow fashion brand is one that focuses on high quality that lasts a long time, and can be repaired. This means using high quality materials, and making each item well. It also means encouraging people to buy one stylish product they will treasure forever, rather than many fashionable items they don’t particularly love which will become victims to changing trends.

A consumer abiding by the slow fashion ideal means someone who works to make their clothes last longer. We shared some tips for this in our blog. These include washing smartly, using green dry-cleaning, and skipping the dry cycle.

Of course, buying high quality products and repairing them is also necessary. It’s not possible to live a “slow fashion lifestyle” when buying fast fashion.

Stock Fabrics

What is a stock fabric?

Stock fabric is existing stock available at fabric suppliers. This is also called deadstock by some, but culthread differentiates between the excess ordered by big brands that is unused (deadstock [LINK]).

Stock fabric is usually warehoused in fabric mills due to small overruns or new fabrics and colours for sampling.

KEY TAKEAWAYS:

- Stock fabric is existing stock available at fabric suppliers

- Stock fabric is usually warehoused in fabric mills due to small overruns or new fabrics and colours for sampling

Understanding stock fabrics

Textile Exchange

What is Textile Exchange?

Textile Exchange is a global non-profit driving positive action on climate change across the fashion and textile industry.

They guide and support a growing community of brands, retailers, manufacturers, farmers, and others committed to climate action toward more purposeful production, right from the start of the supply chain.

KEY TAKEAWAYS:

- global non-profit working towards positive action on climate change across the fashion and textile industry

Visit Textile Exchange's website for more info.

Traceability

What is traceability?

Traceability is the quality of being able to trace a product’s entire supply chain from its origin.

Thanks to globalisation, our product supply chain has become more complex. For example, a material is manufactured somewhere, then shipped elsewhere to make one product piece, then once more shipped elsewhere to be assembled to make a product, shipped elsewhere for the finishings, and finally shipped to a shop which you buy from.

Complex supply chains make traceability tough. However, with new technologies, such as blockchain, traceability is becoming easier.

KEY TAKEAWAYS:

- Traceability is the quality of being able to trace a product’s entire supply chain from its origin.

- Nowadays, given globalisation, supply chains are very complex.

- However, new technologies are enabling clearer tracing.

Understanding Traceability

Traceability’s importance lies in the fact that companies can hide behind untraceable products. For example, companies claim to be sustainable, when the first part of their products’ life (i.e. supply chain) is unsustainable (and untraceable).

To facilitate traceability, we can break it down into traceability tiers.

Traceability Tiers

What are Traceability Tiers?

Traceability is complex. From farm (or PET bottle collection plant) to your doorstep, a product goes through many stages.

To facilitate traceability, we can break these stages into "tiers". With each tier being one step further than the final product.

Tier 1: Factory that produces the final product. This includes all steps from fabric to final garment.

Tier 2: Factory that produces the final fabric. For example, Recycled Vegan Leather, or Recycled Fibre Down Insulation.

Tier 3: Mills that produce the main fabric from raw materials, such as the recycled polyester fabric used for the Recycled Vegan Leather.

Tier 4: Raw Material used to produce the main fabric. For example, the PET post-consumer water bottles used to make the recycled polyester fabric.

KEY TAKEAWAYS:

- To facilitate traceability, we can break these stages into "tiers". With each tier being one step further than the final product.

Vegan Leather

What is vegan leather?

Vegan leather tends to be polyvinyl chloride (PVC) leather, otherwise known as vinyl.

Vegan leather is made by combining polyvinyl chloride with stabilisers which help protect the material, plasticisers to soften and lubricants to make the leather flexible. Then, it is applied to a base material typically made from polyester, cotton, nylon or rayon.

PVC is terrible for the environment, given that it is not biodegradable or degradable- so will retain its form for decades, and creates dioxins - a group of highly toxic chemical compounds which are harmful to health and remain in the environment causing damage for many years after production. Read more about PVC here.

KEY TAKEAWAYS:

- Vegan leather tends to be made by combining polyvinyl chloride (PVC) [LINK], with stabilisers, plasticisers, and lubricant, and applying it to a base material

- PVC [LINK] is terrible for the environment, as it is non-biodegradable and creates dioxins

Understanding Vegan Leather

Vegan leather has been a topic of much debate, as despite it being vegan – it is terrible for the environment. Thus, it has led to people questioning whether “vegan” is actually sustainable. In this case, it definitely isn’t – but that does not mean that there are no sustainable vegan leather options. For example, one could use or buy recycled vegan leather [LINK].

Does vegan leather actually benefit animals?

Even though faux leather materials such as PVC prevent any harm coming to animals in the production of their product, animal life is unfortunately harmed due to the continual build-up of non-biodegradable material in the world’s ecosystems. These smaller pieces of PVC can be ingested by animals which can lead to blocked airways and other harmful consequences.

What about the quality of vegan leather?

PVC is unrealistic in appearance when comparing it to real leather and also much less breathable and prone to cracking. It is however very durable due to its multiple layers and capable to withstand more extreme wear and weather conditions.

Check out our long-form Cultruth Explainer about everything you need to know about leather.

Water-Based Coating

What is water-based coating?

Coatings tend to be used to make a material water-repellent.

A water-based coating is made up of various percentage chemical components dispersed in water. This is in contrast to C6 and C8 coatings, which are toxic for humans and the environment.

KEY TAKEAWAYS:

- Water-based coatings are water-repellent coatings made up of various percentage chemical components dispersed in water

Understanding water-based coating

PFAS

PFAS stands for per- and polyfluoroalkyl substances. They provide lightweight water and stain resistance, and used a great deal in fashion.

If it doesn't say PFAS-free, it likely contains PFAS.

PFAS have significant toxic effects , including being linked to a variety of cancers, reproductive disease, miscarriage, infertility, hormonal disruption, immune suppression and weight fluctuations, to name just a few things.

They're persistent and bioaccumulative, traveling around the globe and building up in our bodies, as well as the bodies of wildlife.

- PFAS stands for per- and polyfluoroalkyl substances.

- They are primarily used as water repellent

- They are toxic substances which have significant harmful impact on our Planet, People, and Animals

PFAS has a chain of carbon and fluorine atoms. The original version that you might have heard of were PFOS or PFOA, “longchain” or C8 fluoroalkyl substances, with eight carbon atoms.

They are used in most water repellent objects, including of course waterproof jackets.

They can shed off of outdoor gear and into your home’s dust, which you can breathe in, or migrate from your clothing to your skin.

And they're persistent and bioaccumulative, traveling around the globe and building up in our bodies, as well as the bodies of wildlife.

Tides are turning: people are becoming more aware and both New York State and California have both banned PFAS in everyday apparel by 2025.

Read more about the details of PFAS in jackets, and how culthread is PFAS-free here